Lin Hong, President of Scinosen: Standardization and self-discipline are key factors driving the progress of enterprises

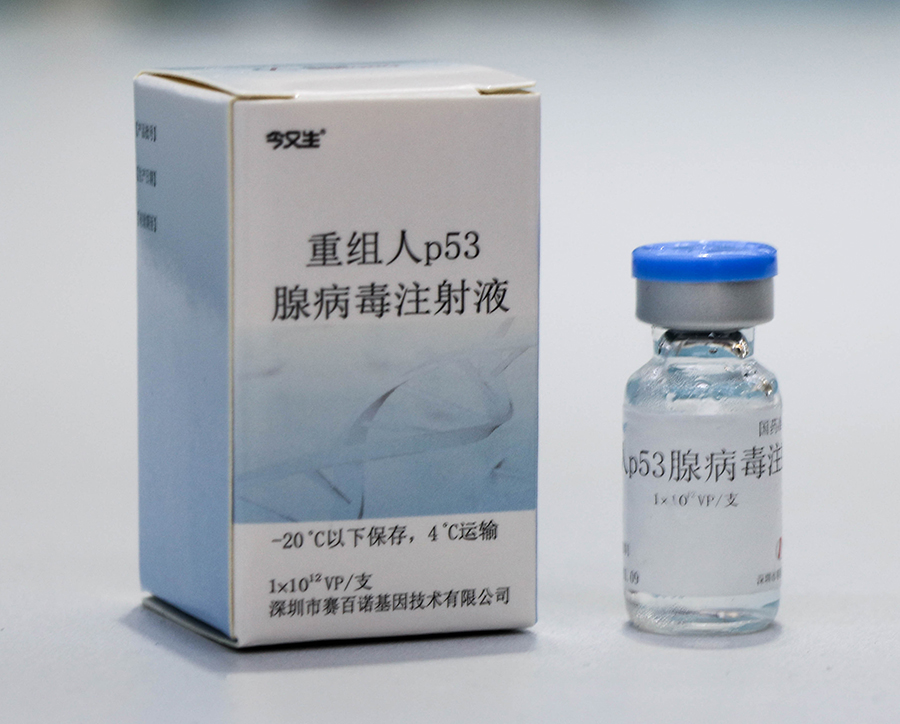

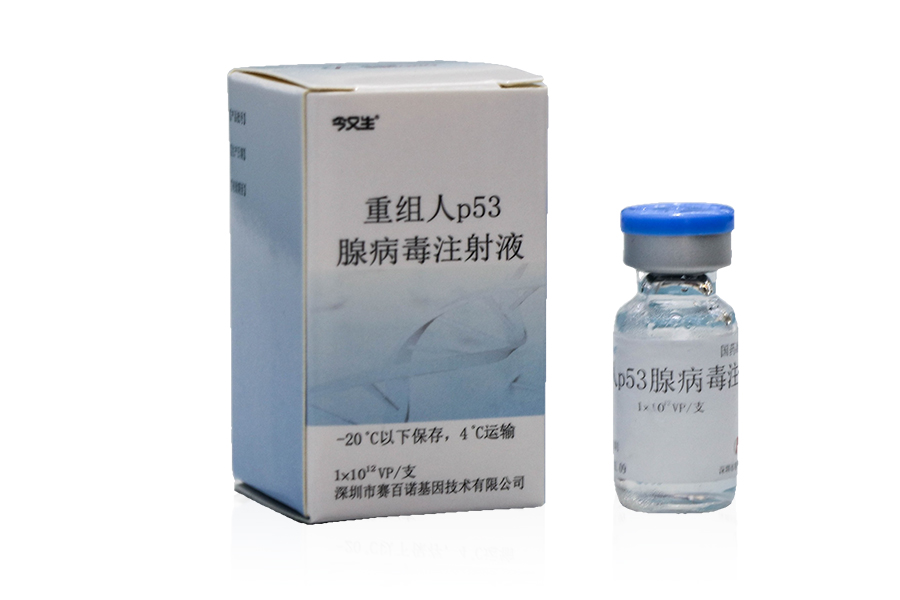

August 13, 2019/Fengke Interview FENGClub/-- As a pioneer in the field of gene therapy in China, the recombinant human p53 adenovirus injection (now known as Yousheng/GCndicine) independently developed by Saibainuo Company obtained the CFDA wholesale new drug certificate as early as 2003, becoming the world's first gene therapy new drug to be officially approved for market.

In May 2018, Sinopharm (Shenzhen) Gene Industry Group's virus vector gene drug CDMO platform passed the inspection and approval of Guangdong Provincial Drug Administration, providing integrated services of "contract research and development+customized production" for enterprises and related institutions in key links from preclinical research and development to commercial production.

What are the considerations behind the transformation and upgrading from developing a globally leading gene drug enterprise to establishing a large-scale CDMO platform for viral vectors? Recently, at the first Global Biopharmaceutical CDMO Development Summit Forum hosted by Yimaike, Dr. Lin Hong, President of Sinopharm, was interviewed by Fengke and shared the development process, industry status, and trends of Sinopharm.

▲Dr. Lin Hong, President of Scinosen, a pioneer in gene drug CDMO

The original intention of establishing CDMO platform

Lin Hong said, "Currently, based on the independently developed gene therapy anti-cancer drug 'recombinant human p53 adenovirus injection', Saibainuo has established a set of large-scale production process technology standards and quality control technology standards for recombinant adenovirus products. We have seen the shortcomings of this industry in the creation process, and we have also experienced many difficulties ourselves. Therefore, we want to share our experience with everyone, which is also the original intention of our CDMO platform. For example, many companies often encounter bottlenecks in the process of developing and producing new drugs, which are products made according to their processes that are not qualified but difficult to find the reasons. Relying on Sinosheng's own core intellectual property rights, strong professional talent team, and years of industrialization system and experience, we can help them analyze where problems have occurred, improve processes, establish standard operations for production processes, develop quality standards, and pass testing according to registration standards

In June 2017, Sanofi CDMO platform signed a tripartite agreement with Sequoia Cardim Pharmaceutical Group and Sinody Medical Technology Co., Ltd. to collaborate on the Class I biopharmaceutical "Mai Zaitong" (recombinant human fibroblast growth factor adenovirus) project, which has entered Phase III clinical trials in the United States.

In July 2017, the Sainuosheng CDMO platform signed a contract with Hangzhou Yiyuan Biological Co., Ltd. to form cooperation on the "Life Beauty" (mutant glucokinase gene adenovirus) project for the treatment of type II diabetes with a new class of biological drugs.

At present, Sainuosheng focuses on three major technical platforms for cancer, diabetes and cardiovascular disease treatment. By using the established gene therapy agent research and development platform, industrialization platform and marketing network, it actively introduces a batch of gene therapy agent research products with clear prospects at home and abroad, and vigorously supports and promotes its industrialization and marketization on the Saibenuo R&D platform. Sinopharm has achieved an annual production capacity of 1.5 million viral vector gene drugs, attracting multiple adenovirus vector gene drug industrialization and research and development collaborations entering clinical practice worldwide.

Three innovative technologies strictly control virus quality

Lin Hong told reporters that gene drugs usually use viruses as carriers and require virus growth, virus harvesting, virus purification, and virus concentration under GMP conditions. Each step has a high technical threshold, and the high threshold of production technology restricts the large-scale production of gene drugs, which determines the price and wide application of gene drugs.

In terms of regulation, it is difficult to establish all aspects that comply with cGMP (Current Good Manufacturing Practices) in the early stages of clinical trials. In addition, there is a lack of standardized analytical methods for evaluating the efficacy and safety of carriers. In terms of transportation, virus manufacturing requires cryopreservation at temperatures much lower than most biological agents. This means that the manufacturing of viral vectors requires a higher level of customizability and manufacturing expertise.

According to her introduction, the Sinovac virus production platform ensures safe and effective production at every stage through a series of processes such as cell recovery and amplification, virus inoculation, purification, formulation, and packaging. The production capacity of each batch of ******* can reach 1.0 × 1017 VP. This is closely related to Sanofi's three innovative technologies:

Firstly, Sinosheng has mastered large-scale animal cell culture technology: the successful production process of 14L Bioreactor adherent cells has achieved a yield equivalent to five times that of the same volume suspension cell culture process reported in foreign literature.

Secondly, Sainuosheng has established the ProFlux M60 system and Auto BioProcess System one-step column chromatography purification technology: ① The purity of the final product has been increased to over 98%; ② The sample loss was significantly reduced, and the overall yield increased to over 30% The processing time has been shortened from 8 working days to 2 working days, ensuring the biological activity of the final product recombinant adenovirus.

Thirdly, Sinopharm has mature application in real-time HPLC quality monitoring technology: high-performance liquid chromatography (HPLC) analysis method can achieve rapid and accurate online detection of recombinant adenovirus yield throughout the product production process. The detection process is fully automated program controlled, eliminating human interference, easy to operate, and only takes 30 minutes to complete sample determination.

Lin Hongtan proudly said, "These technologies fill the gap in the industrialization of genetic biology in China. Now we have applied for four patents around the production process. In addition, due to the special nature of virus products, strict control is required during the production process to prevent side reactions and cross contamination. At the same time, platform based large-scale production also needs to prevent batch differences and pay attention to personnel protection. All of these rely on the continuous improvement of technological level

Standardizing self-discipline to promote positive development of enterprises

In June of this year, the National Pharmacopoeia Committee released the draft of the "General Introduction to Gene Therapy Products for Human Use", which mainly sets general technical requirements for the production and quality control of gene therapy products, with a focus on gene therapy products using viruses and plasmid DNA as carriers. During this period, Lin Hong represented Sinopharm in the formulation of the National Pharmacopoeia "General Introduction to Human Gene Therapy Drugs", and all 14 suggestions put forward were adopted.

Lin Hong recalled, "When we first started making gene drugs, we were pioneers. The world's first gene drug was born in China. Although gene drug research and development has surged in recent years, national regulation has become increasingly strict. In the following decade, the country has not approved any gene drugs to be launched. Gene therapy is very simple, which means that genetically modified viruses, bacteria, or cells are introduced into target cells or tissues with exogenous genes to replace, compensate, block, and modify specific genes, in order to achieve the goal of treating diseases. However, there is a process to make it a drug that can truly benefit humanity. Currently, there are many people developing gene drugs in China, but only a few can truly become drugs in the end. That's right

In July 2015, the General Administration of China issued a notice on conducting self-examination and verification of drug clinical trial data, which was called the "strictest" drug clinical trial data verification in history. As the source and key link of drug development, the quality of clinical trials directly affects the quality and safety of drugs. The authenticity of clinical trial data determines the safety and effectiveness of drugs, and directly affects the safety of public medication. At the beginning of the verification process, the discovery of data fraud and other issues during on-site inspections was shocking, and the vast majority of declared drugs were withdrawn. Although this is a brief pain in the pharmaceutical industry, it is also a price that must be paid in the standardization process. New drug applicants and researchers can only promote the improvement of research and development level and benefit patients with more and better new drugs by transforming the past simple and blind application into emphasizing the clinical value of drugs and dedicating themselves to the development of innovative new drugs.

The key factor that truly drives the progress and development of enterprises is standardization and self-discipline! "Lin Hong said with emotion.